"Oar wrapping sucks. There is no way around it." This was what i was told and came to understand the last time i had to wrap an oar. But wrapped oars can be $30 dollars more than an unwrapped shaft not to mention you cant have the factory wrap oars you make yourself or those antique sticks you have sitting in the garage.

I think that some rowers use leather instead of poly for the tradition. Most oars that i have seen leathered have tacks driven into the oar to hold the leather on. This creates a rot pocked and eventually will be the location for the failure of the oar. But if you want your boat to be a historical replica sometimes leather is the only way to go. If however you want to branch out into the realm of modern but extremely traditional let me introduce you to the serving mallet.

I was working on Powell replica Whitehalls when i stumbled on this chapter from The Marlinspike Salor By Hervey Garett Smith

In my world of boat building (river boats) worming, parccling and serving just seemed a reminder of how bad ass big sailing ships are. Covering wire rope and thin line so that sailors can walk on them without hurting their feet.

A few days later it hit me, a serving mallet would be the easiest way to wrap an oar! No more back wrenching, blister inducing, bile creating nasty wrapping. This might even make wrapping oars fun!

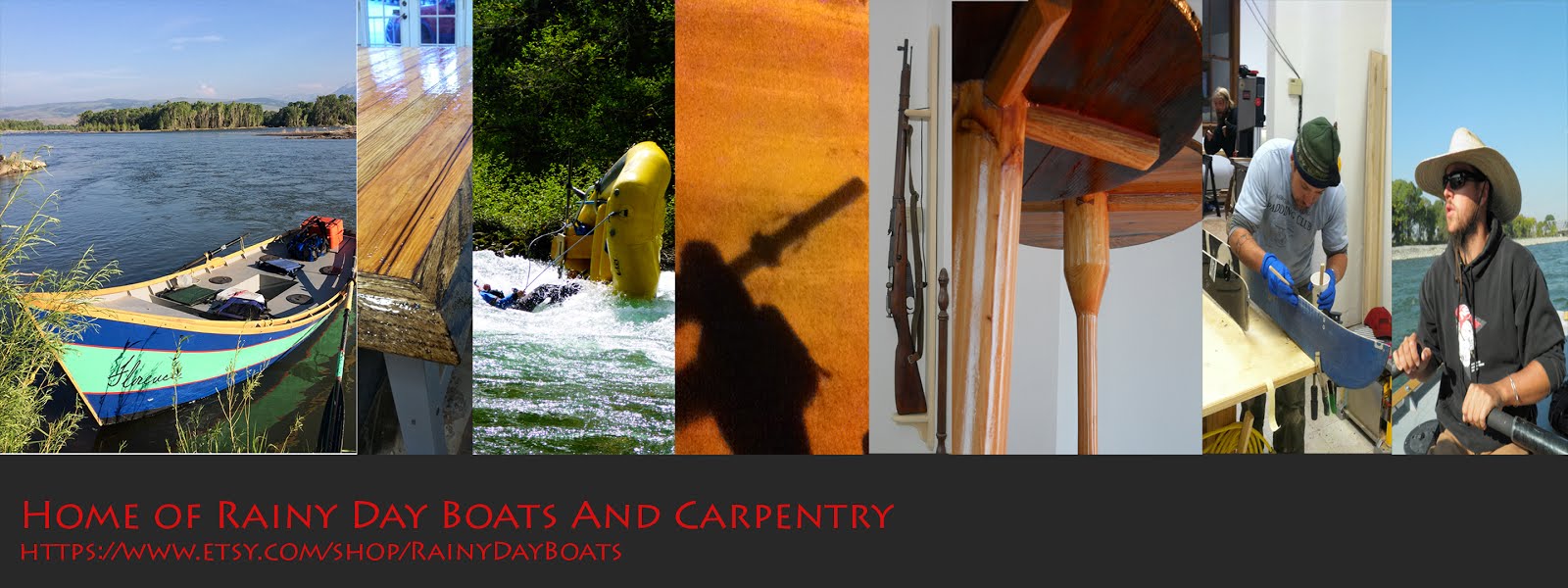

So it was without delay that i whipped up this bad boy. The body and handle are 9" long. I chose Purple Heart for the handle and Ash for the body. I know this is a little fru fru but if you make one for yourself be sure to pick hard durable woods or the poly line will wear right through it.

The body is about 2" thick and hollowed out.

You can see the indents the oar wrapping put into the base of the mallet.

All right lets see how this is done. The first thing you need is some Poly. Unwind it from the factory bundle and wind it onto a dowel or skinny scrap lying around, you will see this a few pictures down.

Figure out how much of the oar you want covered and mark it onto the oar shaft.

***I have now done this three times and by no means have it perfected, if you build your own mallet and find better ways to do this i am all ears!***

Then used e-tape to hold the dead end of the line.

***(Here is where i would do things a bit differently if i had built theses oars. If you can rough up a 3" area where the wrap is to start, mix some epoxy add a little sand, coat the area. When varnishing the oar before wrapping don't varnish the roughed up area. This should give you excellent grip for the first couple of wraps.)***

Double back with several wraps ans tight as you can pull them by hand without the wrap spinning on the shaft. (The oar is firmly secured to sawhorses so it cannot spin.)

Add the Serving Mallet.

This is where it gets fun. After i wrapped the tail in for a few inches i cut off the excess with a utility knife and continued wrapping.

It doesn't take long before your moving along like you know what your doing. So here is how i finally decided to finish off the wraps.

3 or 4" from the end i inserted a loop of poly as seen below and tightly wrapped it in. I secured the end with more e-tape, and fed the spool through the loop.

Now you need to get creative. The force needed to pull the loop through the wrap is astounding, i used a come-along. I have herd of people using sledges and mallets but i just used what i had on hand.

***This part of the process could defiantly be improved by someone**

Finally pull the end through cut it off and add your favorite stops.

Done.

Oh Wait! Here is a picture of a sea anemone and a bridge, enjoy.